Our DC Case Studies

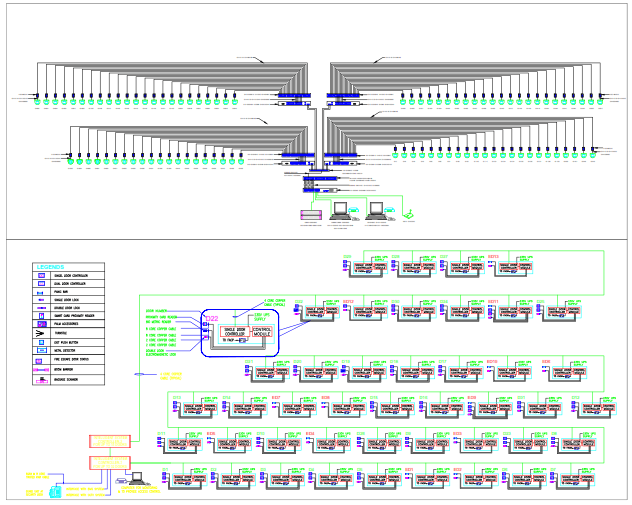

MSI- Sterling & Wilson

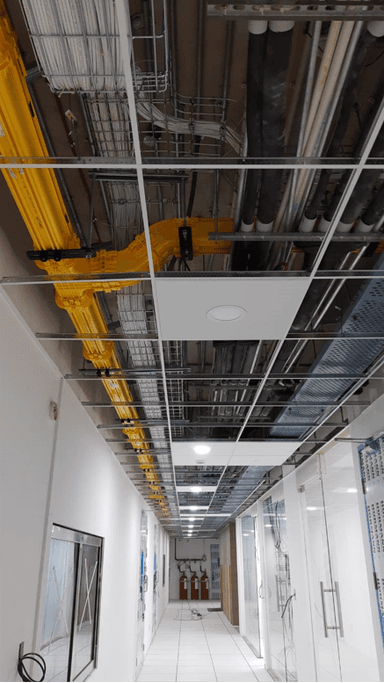

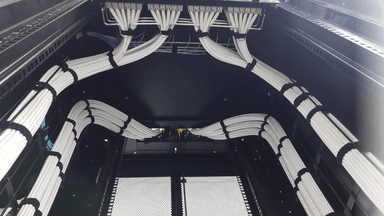

Turnkey Intelligent Structured Cabling designing, supplying and commissioning of ground +6 - storey building and 650 nos 43U racks Data Center System with the involvement of 10 nos in-house design engineers and 50+ skilled technicians, Liasoning works with other stakeholders and etc. Our Intelligent Data Center Structured Cabling Project has achieved the part of Uptime Institute’s Tier IV Design certification.

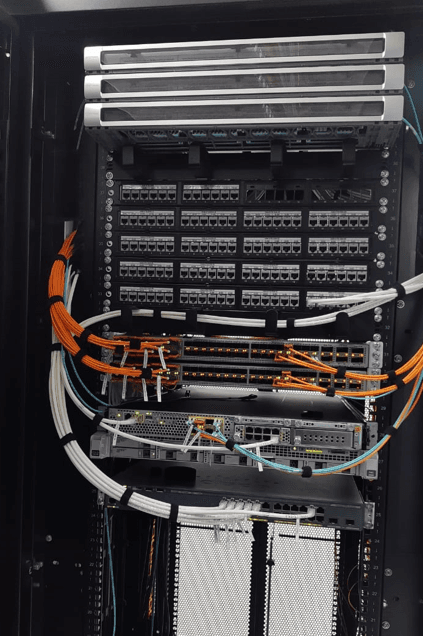

- Use 24 Fiber OM4 Pre-Terminated Rack to Rack Trunk Cable – 33810 Mtr

- Use SM 24 Fiber Pre-Terminated Trunk Cable – 79230 Nos

- Use LC-LC, OM4 MM 10 Mtr 50/125 Patch Cord – 48500 Nos

- OM4, MPO Cassette, 24 LC fibers (12 duplex ports) – 1732 Nos

- 1U Sliding modular cassette shelf, accepts 4 MPO cassettes – 1200 Nos

- LC-LC, SMF Patch Cord – 62000 Nos

- CAT 6A LSZH, ETL Verified Category 6A U/UTP Cable Box – 380 Nos

- CAT6A Patch Cords – 20300 Nos

- Fiber Guide Pathway System – 1558 Mtr

- Cable management wire basket Pathway System – 1200 Mtr

- Use Commscope Intelligent Upgrade Kit for HD Shelf, 6PK Kit – 155 Nos

- Use Commscope Intelligent Upgrade Kit, 5PK Kit – 6 Nos

- Use Commscope Intelligent Ready CAT 6A U/UTP Patch Panel, 24 port – 130 Nos

- Use Commscope AIM Software with unlimited Port License – 1 No

- Use Commscope Software Maintenance Pack for 5 Years

MSI- Sterling & Wilson

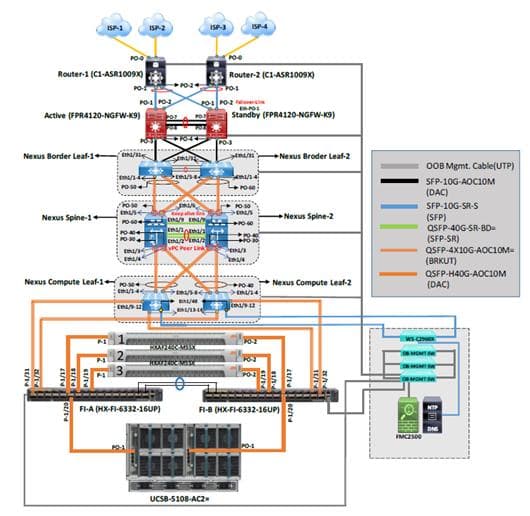

Private Cloud designing, supplying and commissioning of ground +12 - storey building and 100 nos 42U racks Data Center System with the involvement of 15 nos in-house Network and Cloud design and implementation engineers and 15+ skilled passive technicians.

- Use Cisco UCS 5108 Blade Server

- Use Cisco HX 240C M5 Hyperflex HCI System

- Use Cisco Compute UCS B200 M5 Blade System

- Use Cisco UCS 6332-16UP 1RU Fabric Interconnect System

- Use VMware vCenter 6 Server Standard, SUSE Linux, Microsoft Package

- Use Cisco Workload Optimization Manager

- Use Cisco Cloud Management Suite and UCS Director Automation Suite

- Use Cisco ASR1009 Router and Cisco Firepower 4120 Firewall

- Use Cisco Nexus 9504 Chassis as a Spine Switch

- Use Cisco N9K-C93180YC-FX as a Leaf Switch

- Use Commscope MPO to MPO, 12-Fiber

- Use Commscope LC-LC Multimode 50/125 micron OM4 Duplex Patch Cord

- Use Commscope Cat 6A F/UTP 23 AWG Cable

- Use Commscope CAT 6A,S/FTP Patch Cord

- Use Commscope Jack and Patch Panel

- Use Commscope 4 x 4 Fiber Guide Pathway System

- Use Commscope Copper Pathway Wire Basket

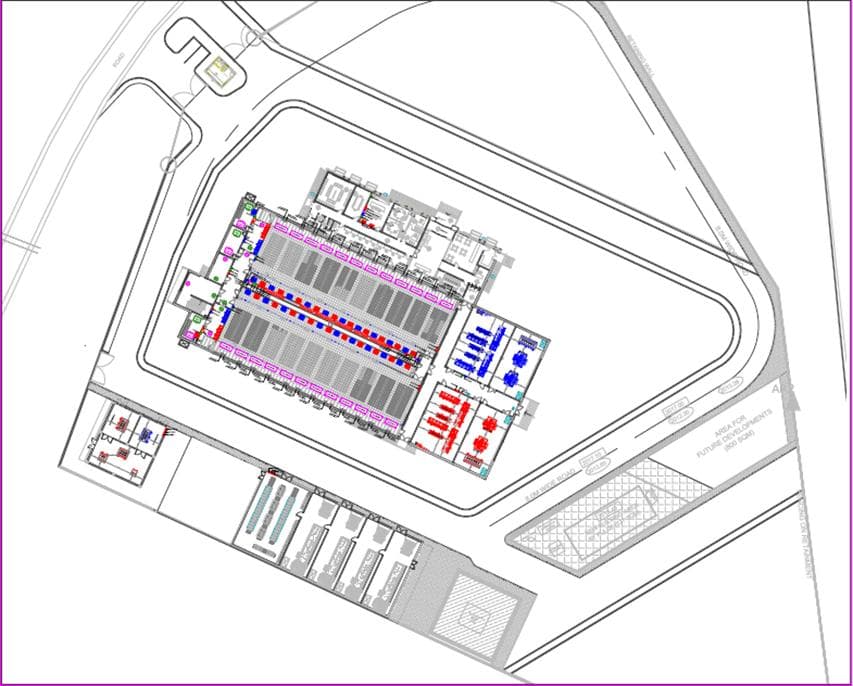

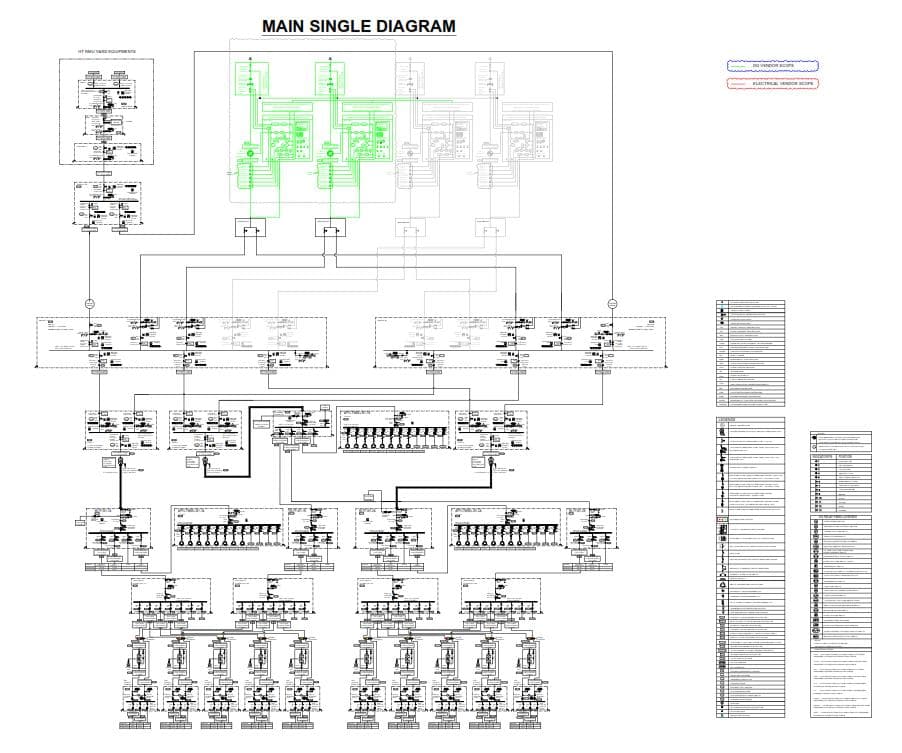

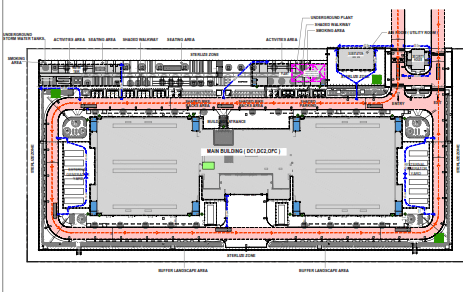

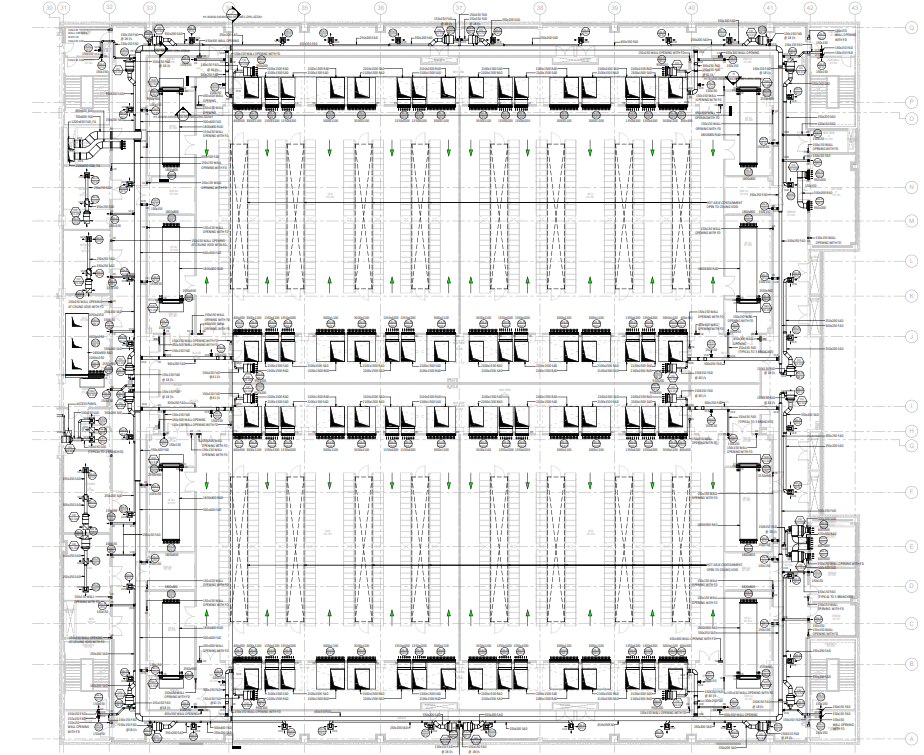

STPI BBSR Data Center Topology

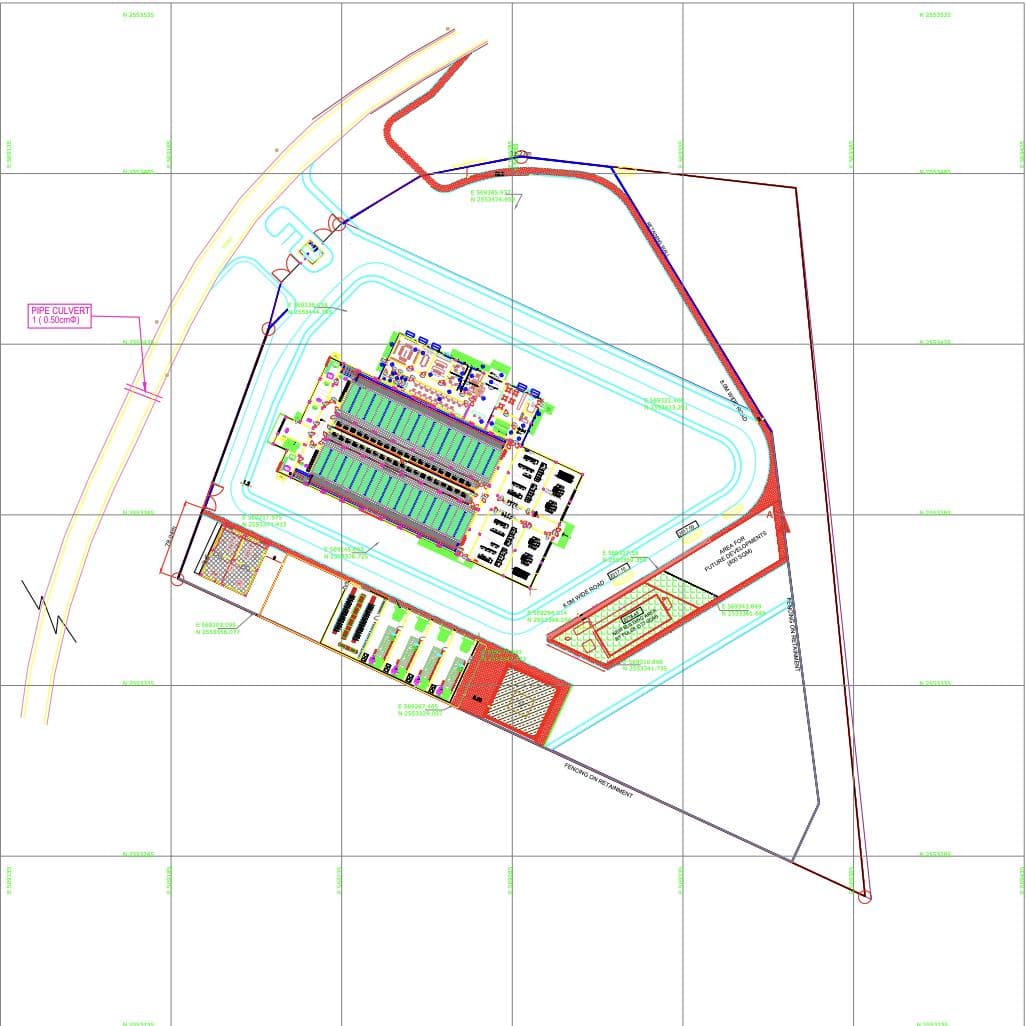

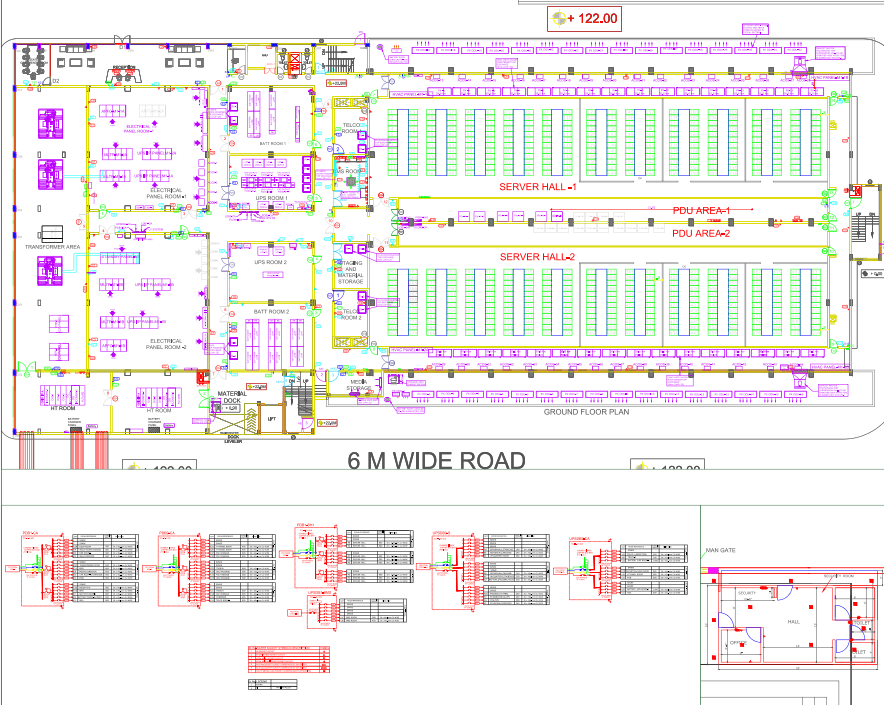

showcase (For a 3.4MW Tier III Greenfield DC in Muscat)

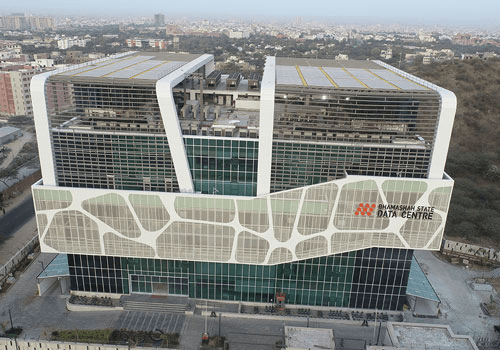

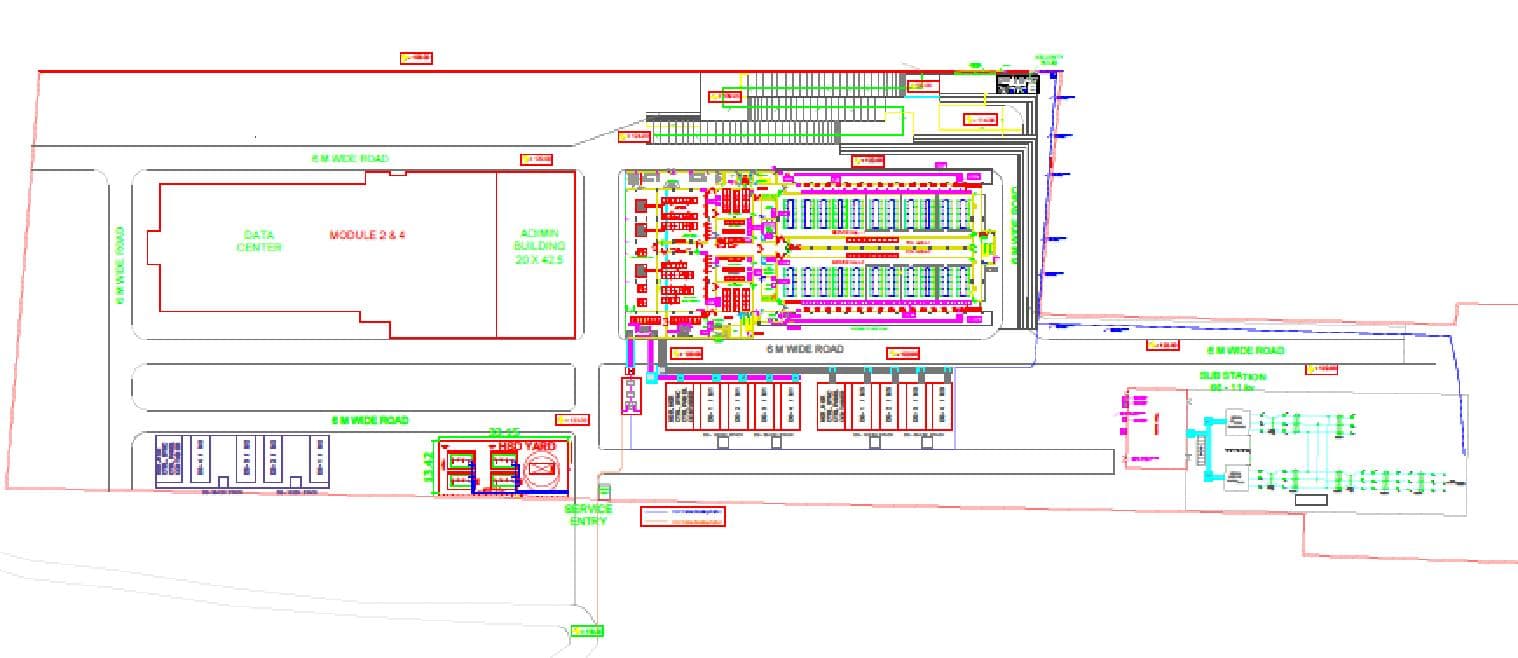

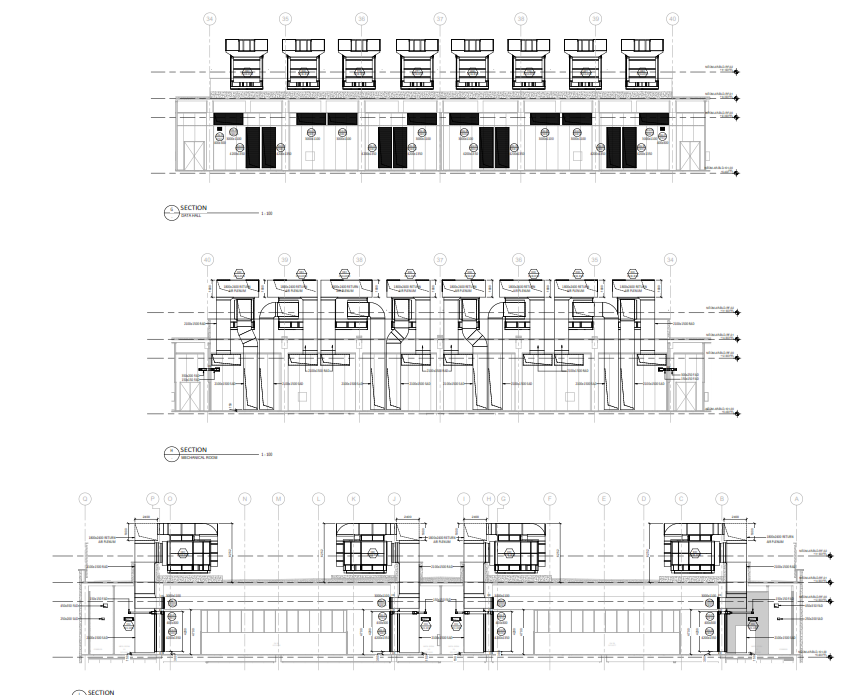

Using 35+ Years of experience a Data center was designed for the Government of Oman, At Muscat, with Tier- III Uptime Institute Certification for Design.

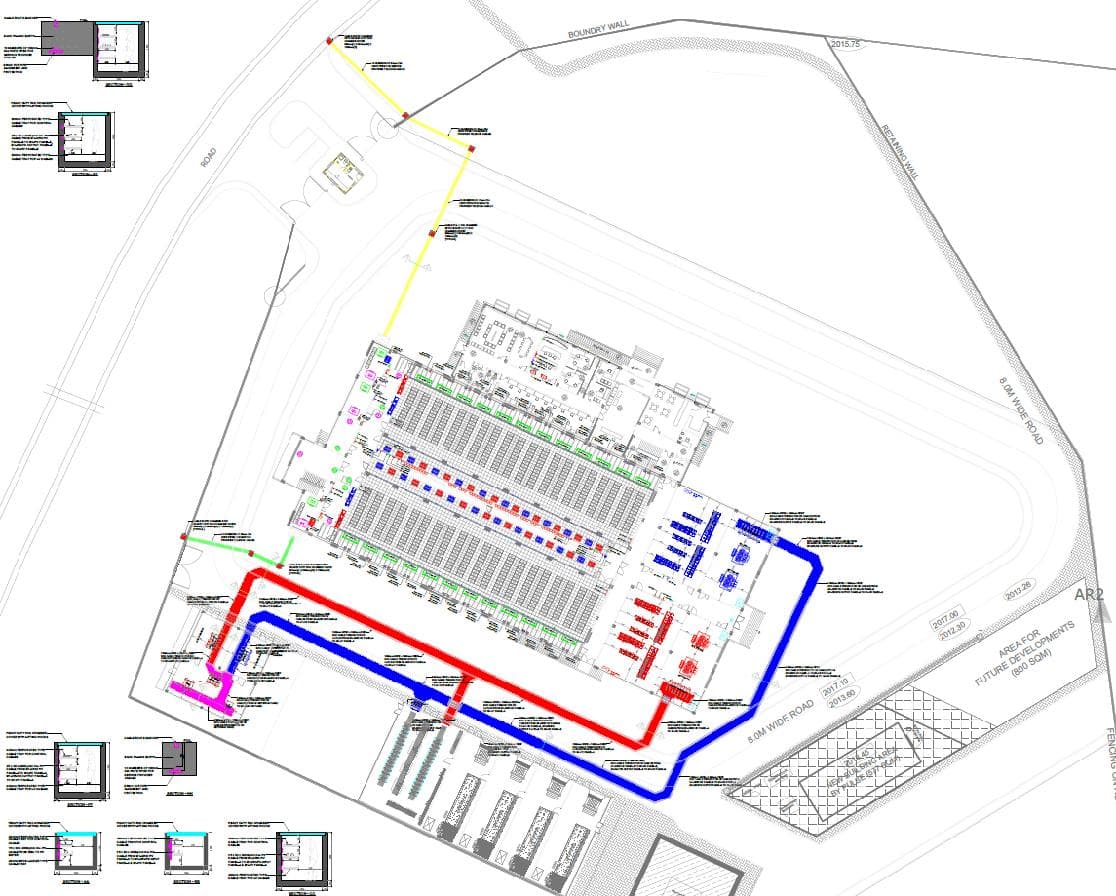

The Site Location was on a Hill of 2000 m above sea level, rocky area, about 4.5 Acres land was allocated.

Space allocated for future development as well as Employees Residential buildings. The IT Load was 2.08 MW. and Facility Load was 3.78 MW

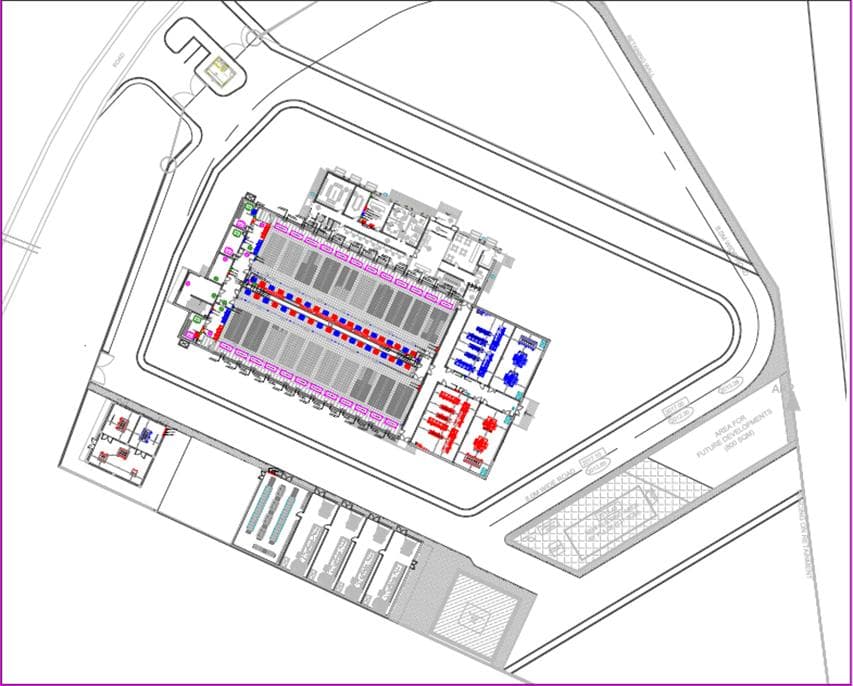

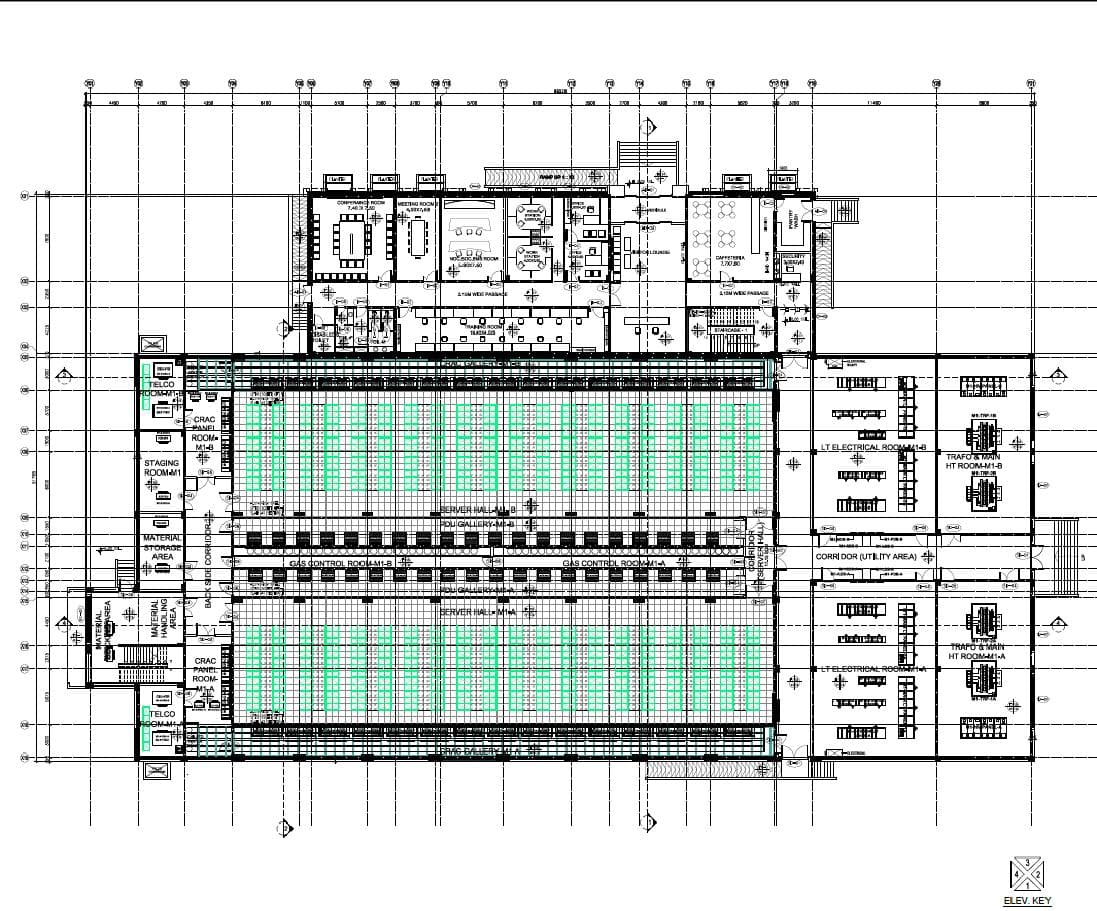

- Space planning done to accommodate 520 IT Racks in 2 Server Halls.

- Dual Telco Rooms, Electrical Rooms, Material handling area, and Office space included.

- Designed facility to meet Uptime Institute Tier-III Standards and obtained Design Certification.

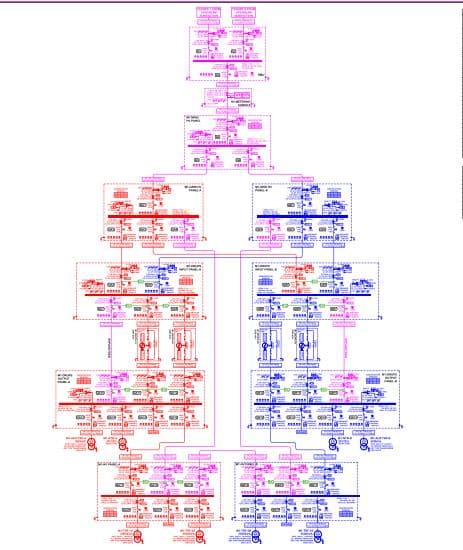

- Electrical System in N+N Configuration with proposed 11 KV Rotary UPS (DR-UPS) feeding Transformers to step down to utility voltage for the entire facility.

- Mechanical System in N+1 Configuration with Chiller Plant on Terrace and CRAH for Server Halls.

- FCUs and AHUs provided for Non-Critical area cooling purposes.

- Novec 1230 Gas system implemented for Fire Suppression.

- BMS, CCTV, EPMS, VESDA, WLD, Access Controls, and FAS integrated into the facility.

- UPS power continuously available for every equipment of the data center, power outlets, and the entire campus.

- All cooling units remained in continuous operation even during power failure conditions.

- Automatic correction of Power Factor ensured stable and efficient operations.

- IT Load: 2.25 MW

- Total Facility Load: 3.78 MW

- No. of IT Racks: 520, Rack Power Density: 4 kW

- Datacenter Rating: Uptime Institute Tier III (Compliant)

- Uptime Certification: Tier-III Design certified by Uptime Institute

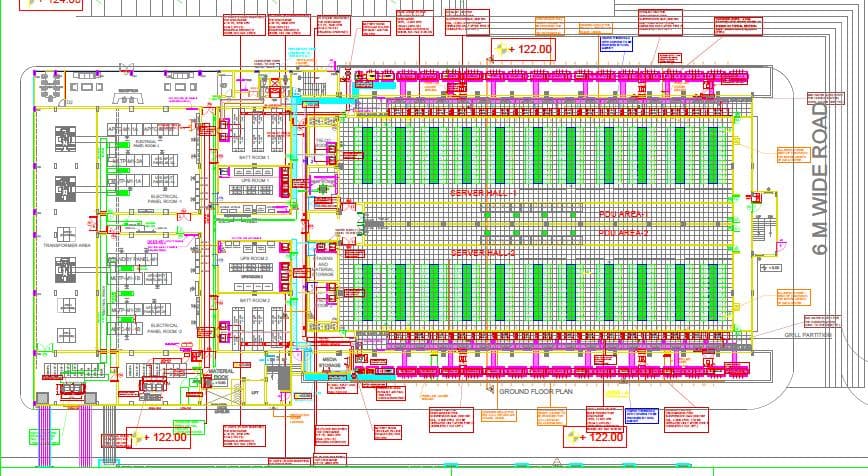

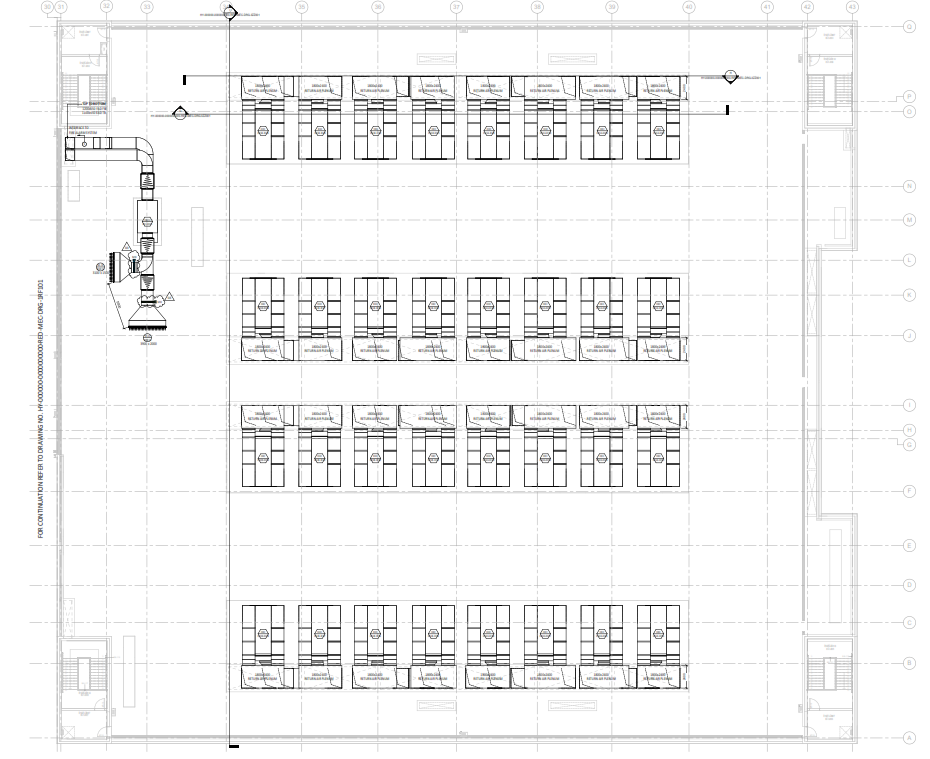

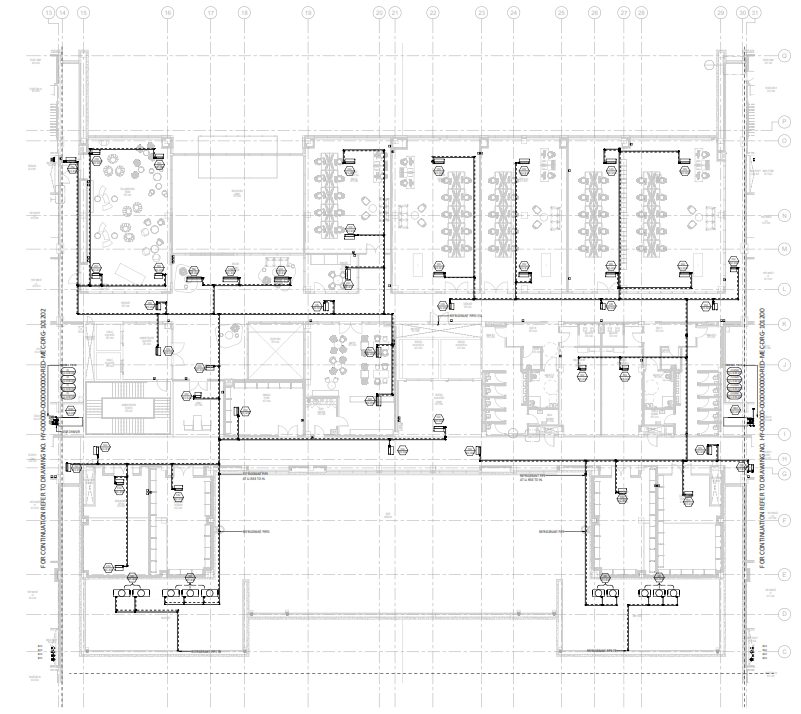

showcase (for a 4.5MW Tier III Greenfield DC in Bangalore)

Designing, Building, Testing, and operating of a Data center at Bangalore meeting to Uptime Institute Tier- III guidelines .

The Site Location was on a Hill of 45 m above road level, rocky area, in a plot of 10 acres land. Hill chopped off to 22 Mtr level from road level and developed the Datacenter.

Net Design Capacity of 28. and Phase – 1 was built for 7.5 MW Capacity.

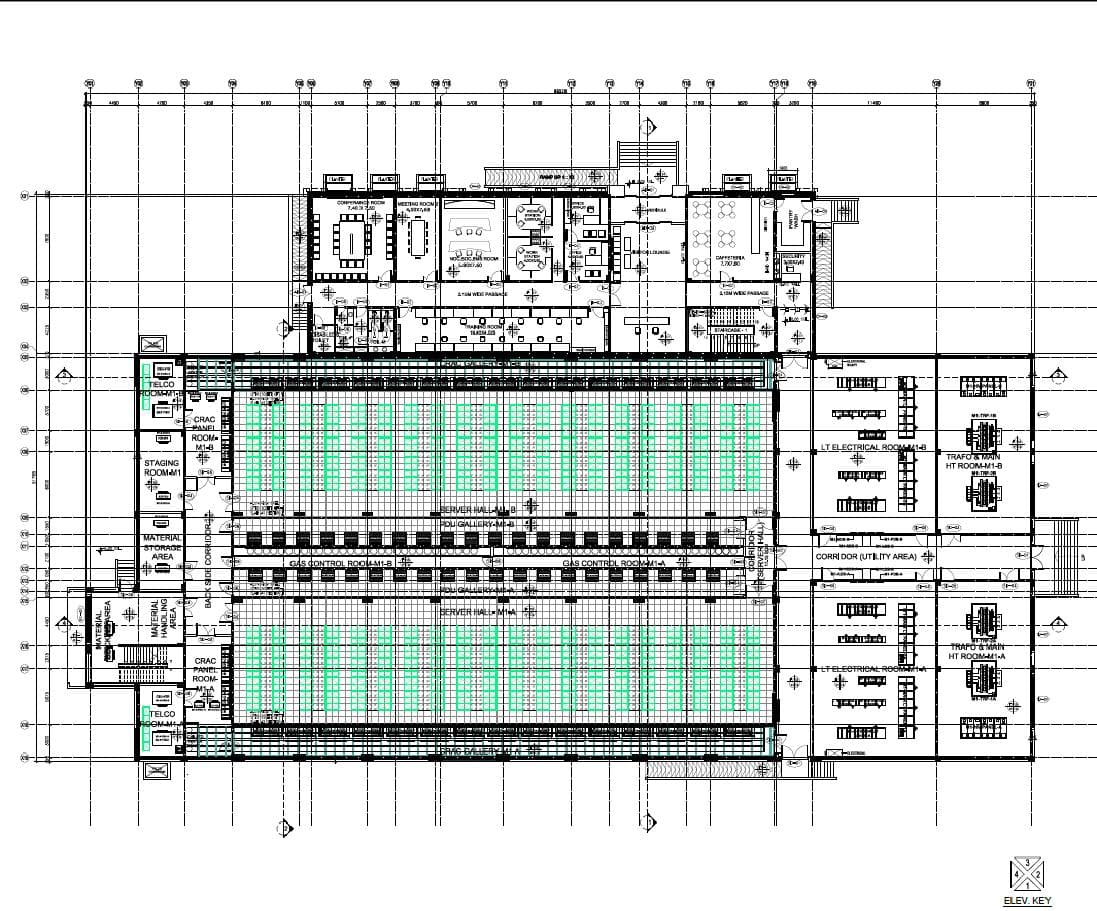

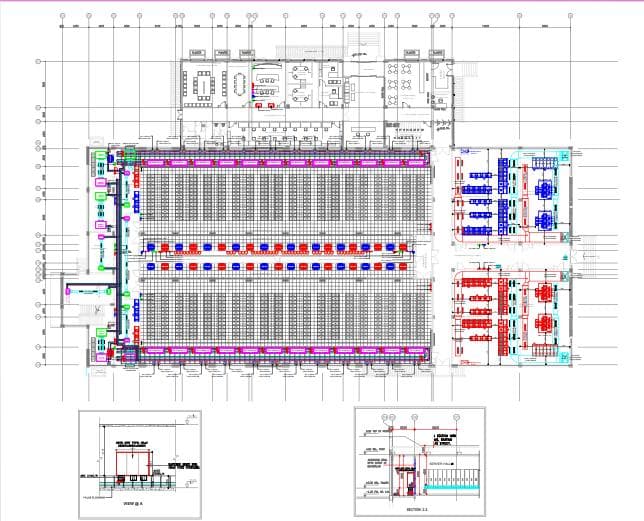

- Facility includes Ground Floor and First Floor with 2 Server Halls on each floor.

- Space planning done to accommodate 264 IT Racks, with Dual Telco Rooms, Electrical Rooms, Material Handling Area, and Office Space.

- Designed to meet Uptime Institute Tier-III Standards.

- Electrical System in N+1 Configuration with 11 KV Rotary Diesel Engine Generators feeding Transformers, stepped down to utility voltage for the complete facility.

- Mechanical System in N+1 Configuration with CRAC units and PAC units for Non-Critical areas.

- FM-200 Gas system implemented for Fire Suppression.

- BMS, CCTV, EPMS, VESDA, WLD, Access Controls, and FAS integrated into the facility.

- Developed Raised Floor of 750 mm height.

- Implemented Cold Aisle Containment to improve PUE efficiency.

- Created separate partitions to isolate IT Space from Non-IT Space.

- Installed indoor units adjacent to external walls with outdoor units placed directly outside, minimizing low-side materials and overall cost.

- Planned power distribution from HT Room to IT Racks in a straight line, ensuring easy identification, reduced power losses, and material cost savings.

- Total Design Capacity: 28 MW, implemented in 4 Phases.

- Phase 1 IT Load: 3.0 MW.

- Total Facility Load: 4.5 MW.

- No of IT Racks: 500.

- Rack Power Density: 5 kW per rack.

- Datacenter Rating: Tier III Compliant.

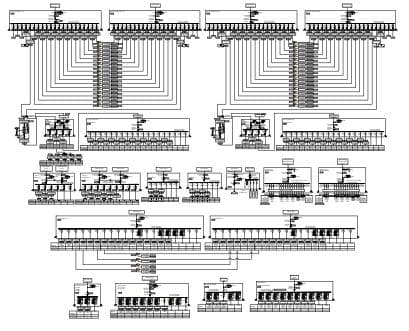

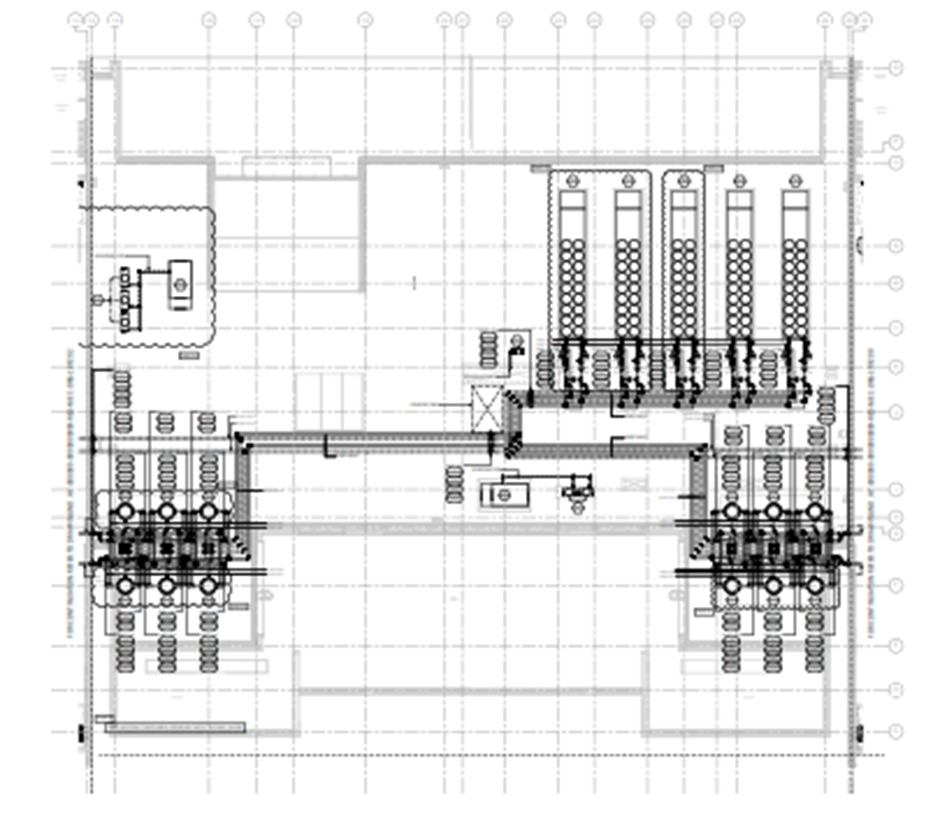

Design Validation and Peer Review of a 20 MW Datacenter developed at Dammam, Saudi Arabia.

- Pear Review of the Design Documents, Design Calculation, Simulation Studies.

- Validating the Design, Equipment Specifications, .

- Preparation of Report, with valid comments, suggestions,

- Validating the Method Statements for installation process, Testing and Commissioning processes, Certification Processes,

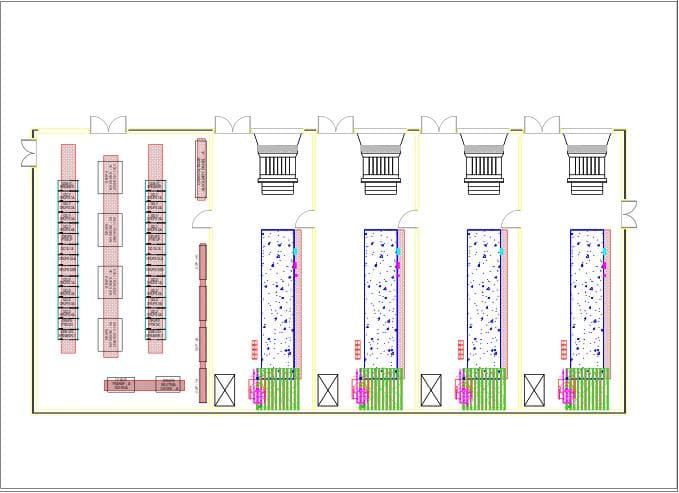

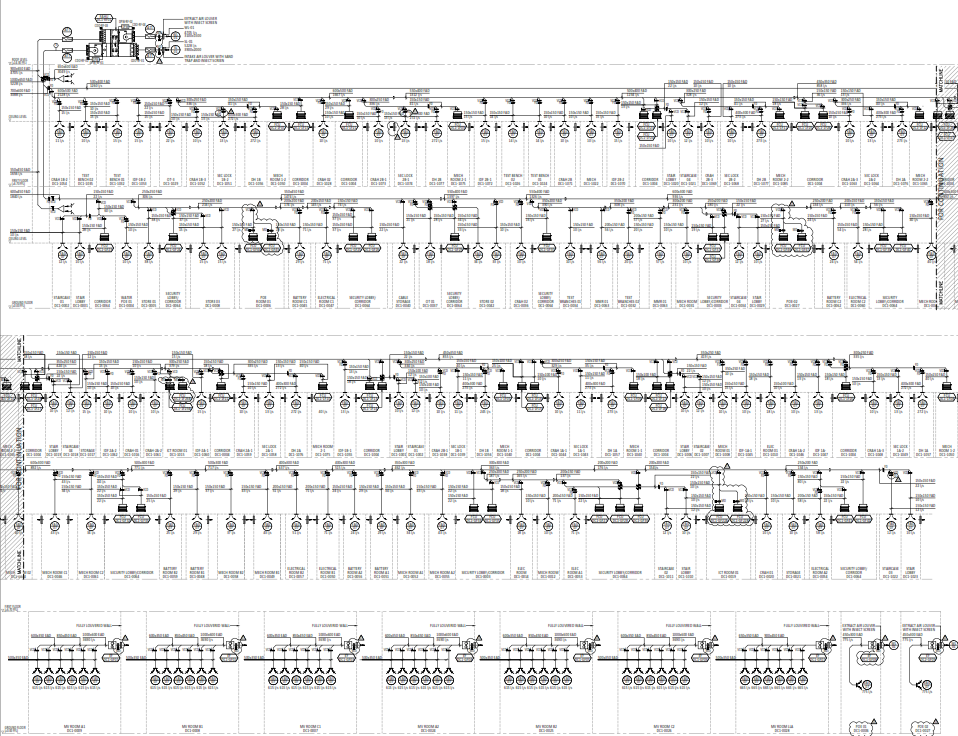

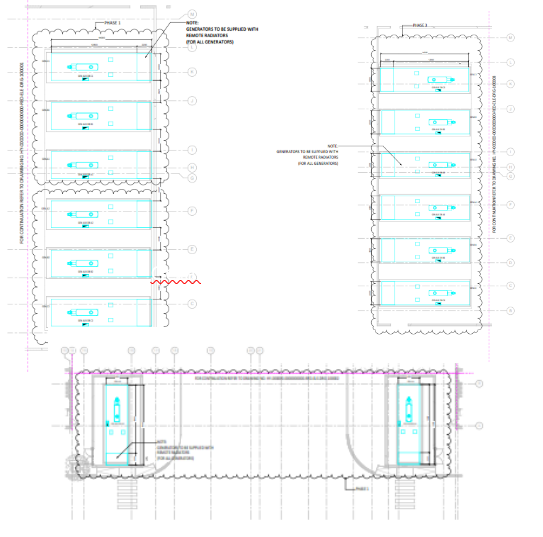

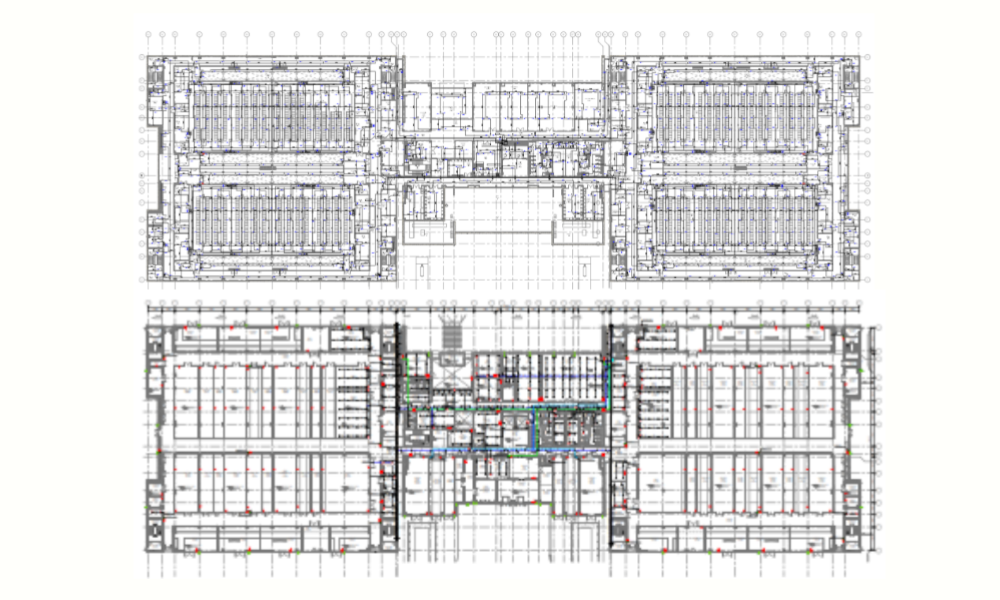

- Ground Floor , Utilities in the ground floor, :- DG Sets Adjacent to Main Bldg, Water Tanks,on periphery, Electrical Room, ICT Rooms

- First Floor, 4 Data hall, Each 5 .0 MW, Hot Aisle Containment, All Control Rooms,

- Terrace , Chiller Plant, IDEC Units, Pumps and Accessories.

- Terrace: Chiller Plant, IDEC Units, Pumps, and Accessories.

- Terrace: Chiller Plant, IDEC Units, Pumps, and Accessories.

- First Floor : 4 Data hall, Each 5 .0 MW, Hot Aisle Containment, All Control Rooms,

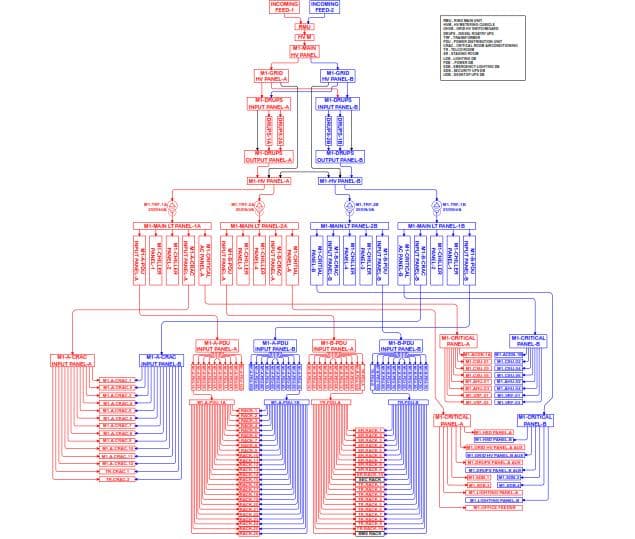

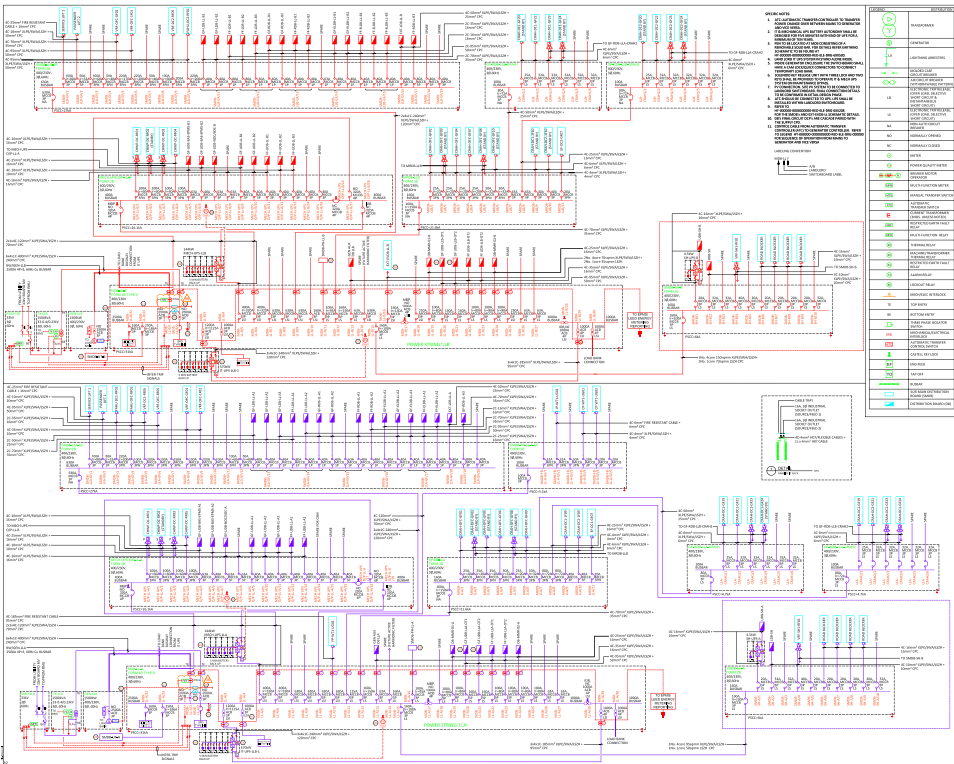

- Electrical Single Line diagram ( Typical)

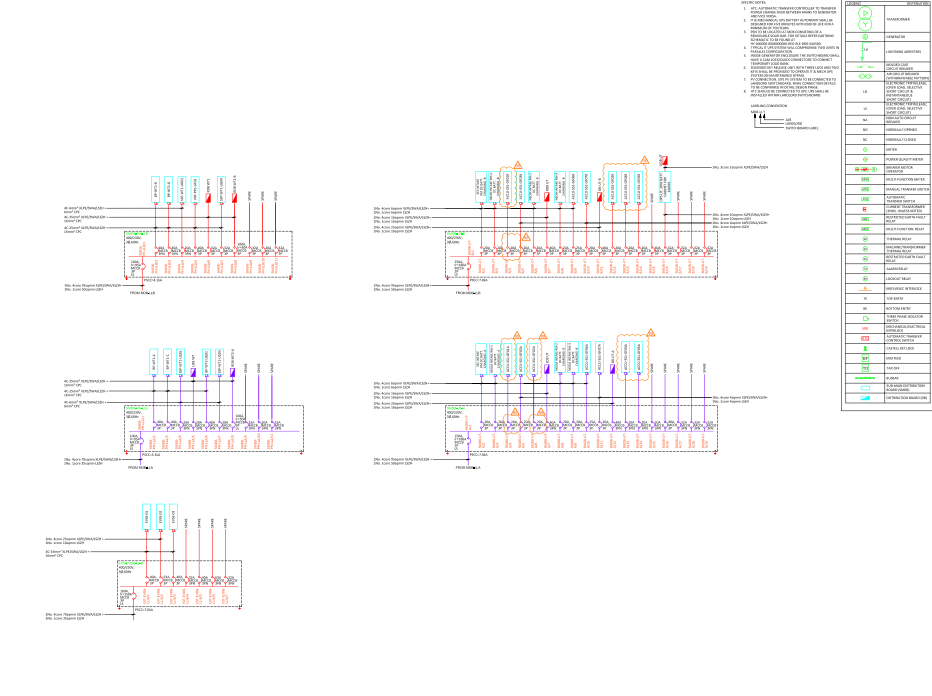

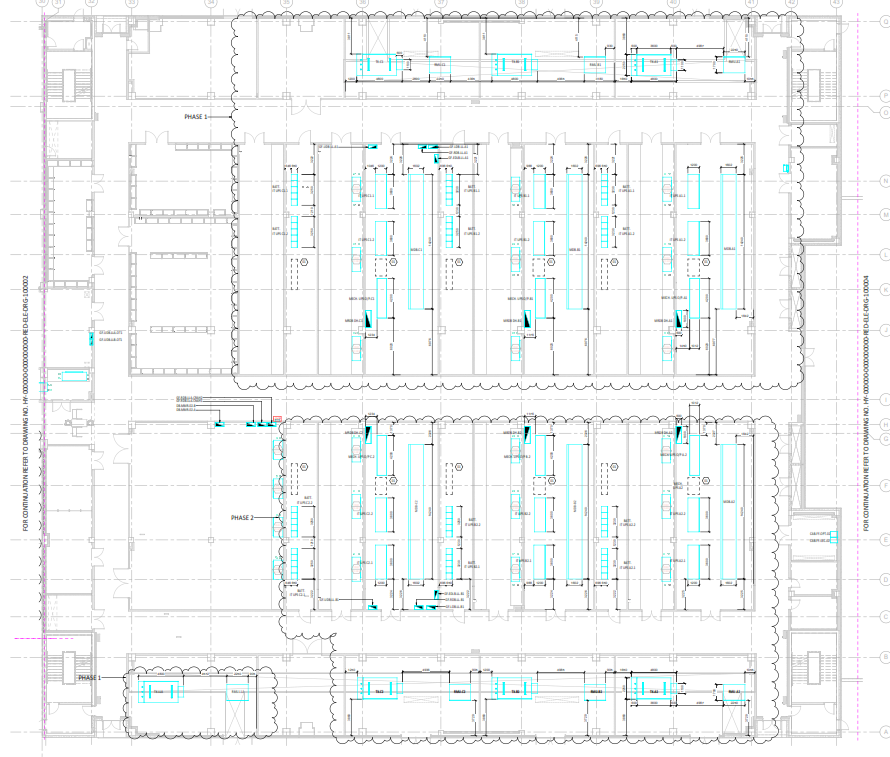

- Electrical Room Equipment Layout, Generator yard Layouts

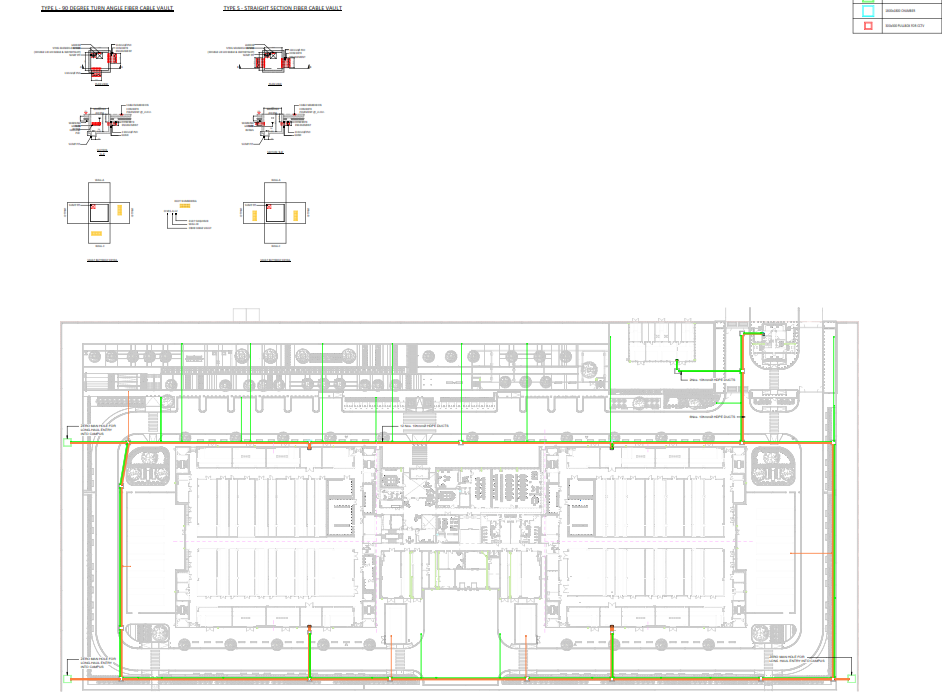

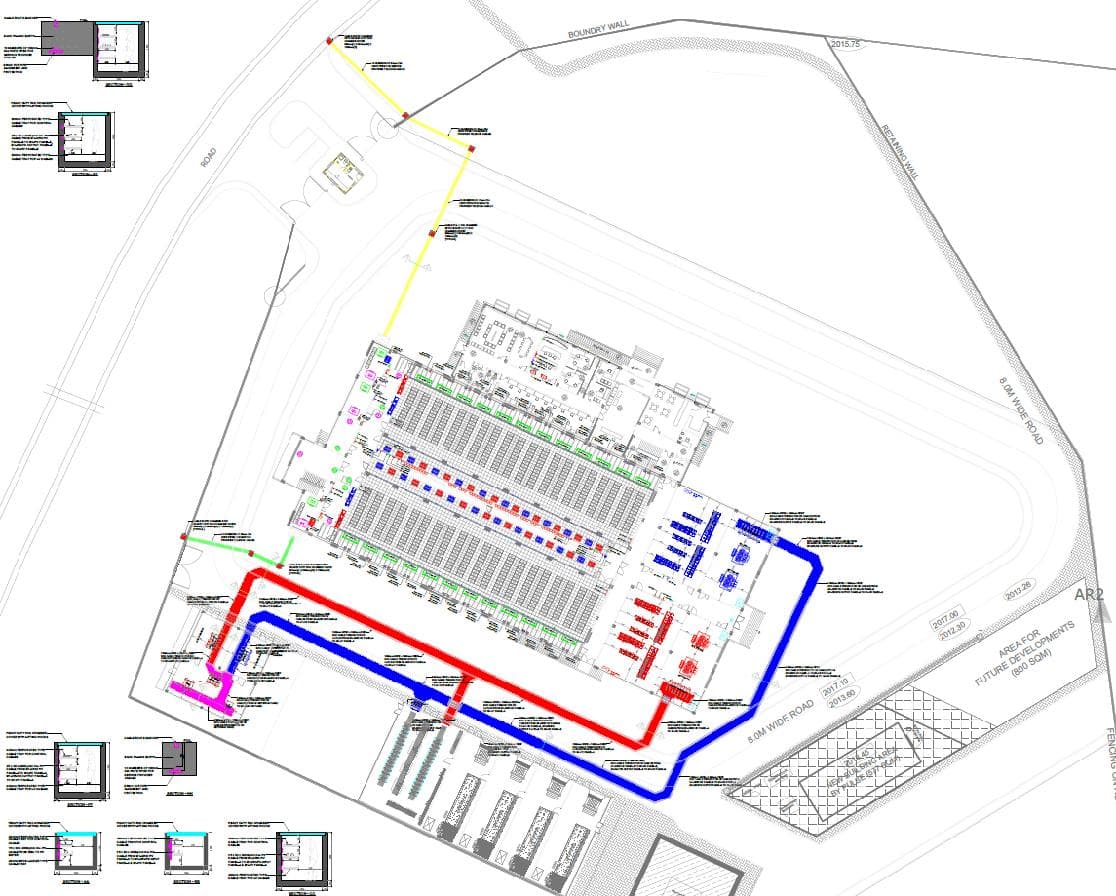

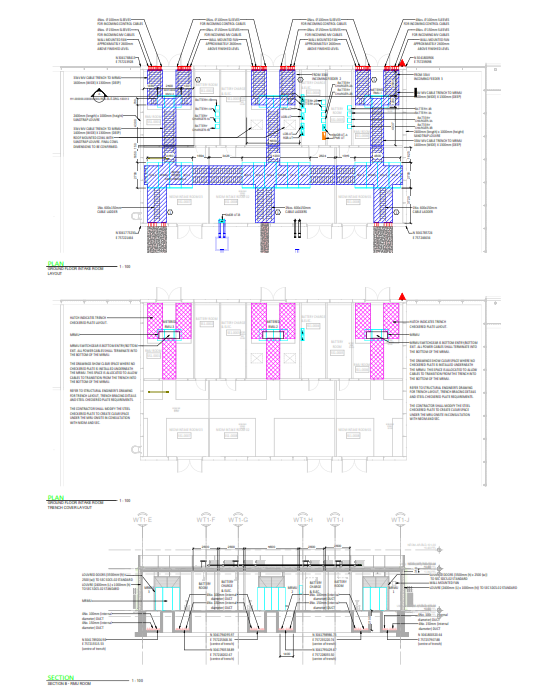

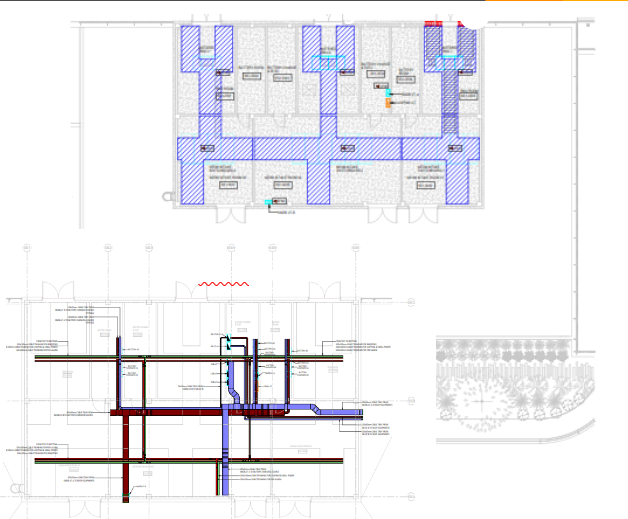

- Utility Building Laout, Trench Layout, Typical Cable tray Layout

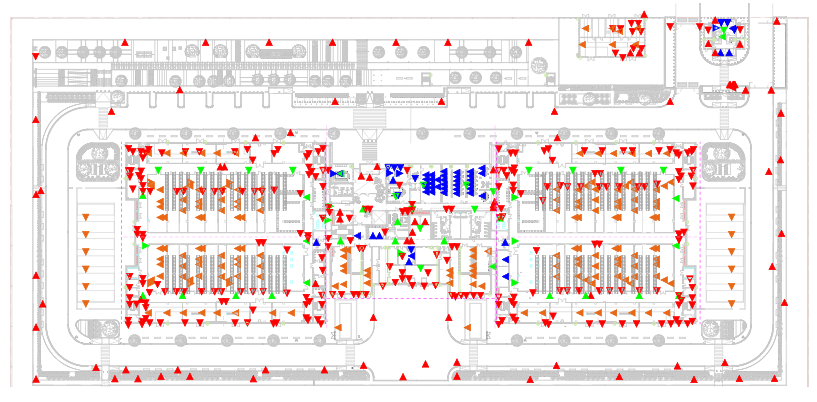

- Fire Alarm System First Floor Master Plan

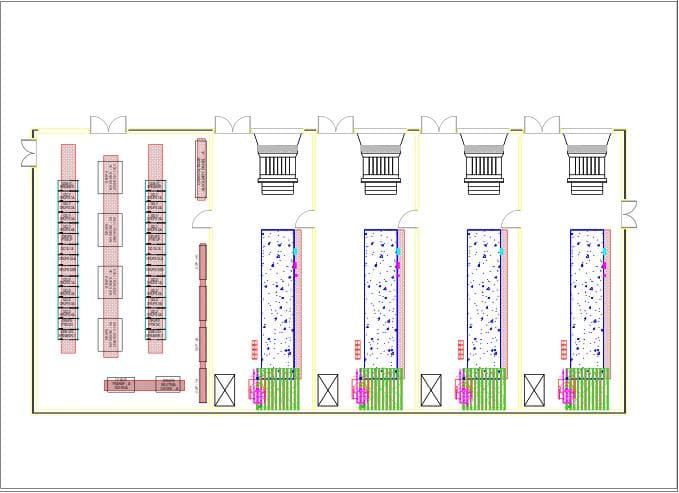

ICT Layout

Fibre path to DC building and Internal Trench arrangement